Metrology

Design Unit: Our Services

The laboratory facilities include:

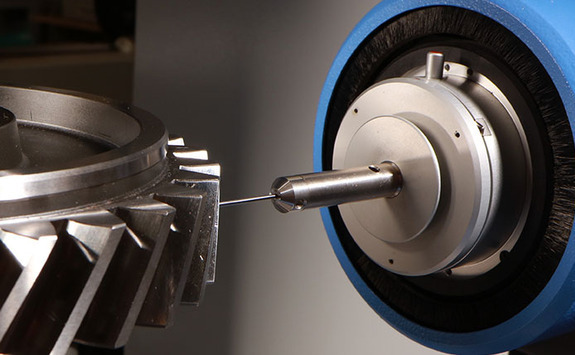

- Enhanced Klingelnberg P65 Gear Measuring Centre, used as the reference calibration and measurement machine

- Leitz PMM-C

- Taylor Hobson Form Talysurf 50 surface roughness and form measuring instrument

- Alicona Infinite Focus G4 optical dimensional and surface roughness measurement

- Hexagon Absolute Romer 7-Axis Arm 8520 with RS5 Laser Scanner

Accreditation

NGML are accredited by the United Kingdom Accreditation Service (UKAS) to ISO 17025:2017 for the measurement and calibration of gears. We are traceable to primary calibration facilities at:

- the National Physical Laboratory (NPL) in the UK

- the Physikalisch-Technische Bundesanstalt (PTB), the national metrology institute of Germany