Test Rig Development

Design Unit: Our Services

Back-to-Back (power recirculating) Gear Test Rigs

These rigs are in both 91.5mm and 160mm centre distance.

In house, they are typically used for gear fatigue testing but are also suited to material and lubrication research and testing. They are characterised by the use of servo-hydraulic control of test torque. This allows variation of the applied torque throughout testing. It includes two test gearboxes rather than a single test and coupled 'slave' gearbox.

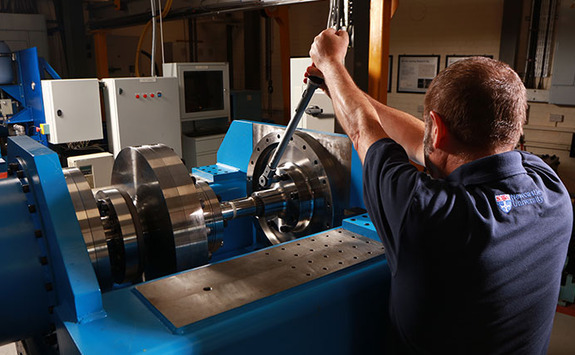

Bearing Test Rig (BTR)

This rig is capable of high load testing of rolling element bearings. Further configurations allow full-scale testing of journal bearings. The BTR is able to apply radial loads of up to 3500 kN. It logs crucial test parameters such as vibration, torque to turn, temperature and power.