Research Theme: Modelling of Materials and Structures

We investigate the processing-microstructure-properties-performance relations of materials.

Structural optimisation

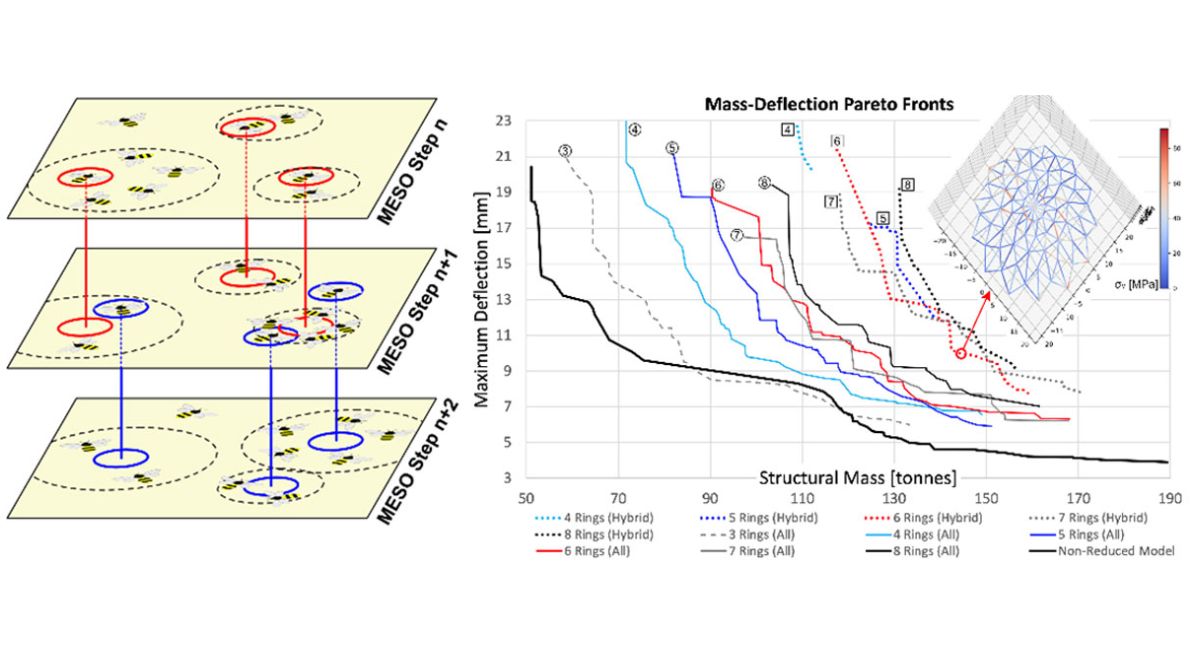

Structural optimisation addresses the complex nature of many engineering structures. They may have tens, or even hundreds, of parameters. Some are continuous, such as the radius of a dome roof or the position of a circumferential girder. Others are discrete, such as the number of radial girders or the type of industrial section used for each girder.

Structural optimisation is multi-objective in nature. There is a need to minimise manufacturing cost: for example, by reducing mass. We must do this without sacrificing structural response and safety. This could include, for example, reducing deflection. These objectives can conflict.

Optimisation methods are evolutionary. They change incrementally from an initial design.

Metaheuristics are problem-independent techniques. Optimisation methods are also metaheuristic. They are often trial and error based.

Many metaheuristic algorithms are nature-inspired, such as the Bees Algorithm.

Optimal solutions are rare. The best algorithms may incorporate aspects of:

- the engineering knowledge and experience of evolutionary structural methods (such as MESO)

- the intuition of random searches