Marine, Offshore and Subsea Technology Facilities

We have a wide range of marine technology facilities at our disposal for teaching and research. Find out more about the impressive facilities available to you at the School of Engineering and take a virtual tour.

Cutting edge facilities

We have a variety of cutting-edge marine technology facilities that are available for you to hire. Within the School of Engineering you'll be able to work in the Marine Propulsion Research Laboratory. This facility includes:

- Emerson Cavitation Tunnel

- multi-purpose flume

- slime farm

- Flow Cell

- Princess Royale (our research vessel)

Find out more

Models and workshop capabilities

We have dedicated workshops that provide maximum flexibility in setting up models, jigs, and fixtures, and adapting test programmes to suit client needs.

We are able to work with models provided by clients, but we can also draw on a range of highly skilled external model makers to manufacture models to client designs, ready for us to adapt to our test equipment.

Please contact us to discuss the options that are available.

Instrumentation

We offer a wide range of instrumentation, which we adapt to suit individual test scenarios. This includes:

- a range of load cells

- six axis devices

- vectrino 3D ultrasonic water sensors

- pitot tubes

- differential pressure sensors

- the Qualisys IR Tracking System

Contact

For further information, contact:

Weichao Shi

Reader, BEng, MEng, PhD, MRINA, FHEA

Net Zero Maritime Systems (Marine renewable energy and marine propulsion)

Tel: +44 0191 208 6722

Email: weichao.shi@newcastle.ac.uk

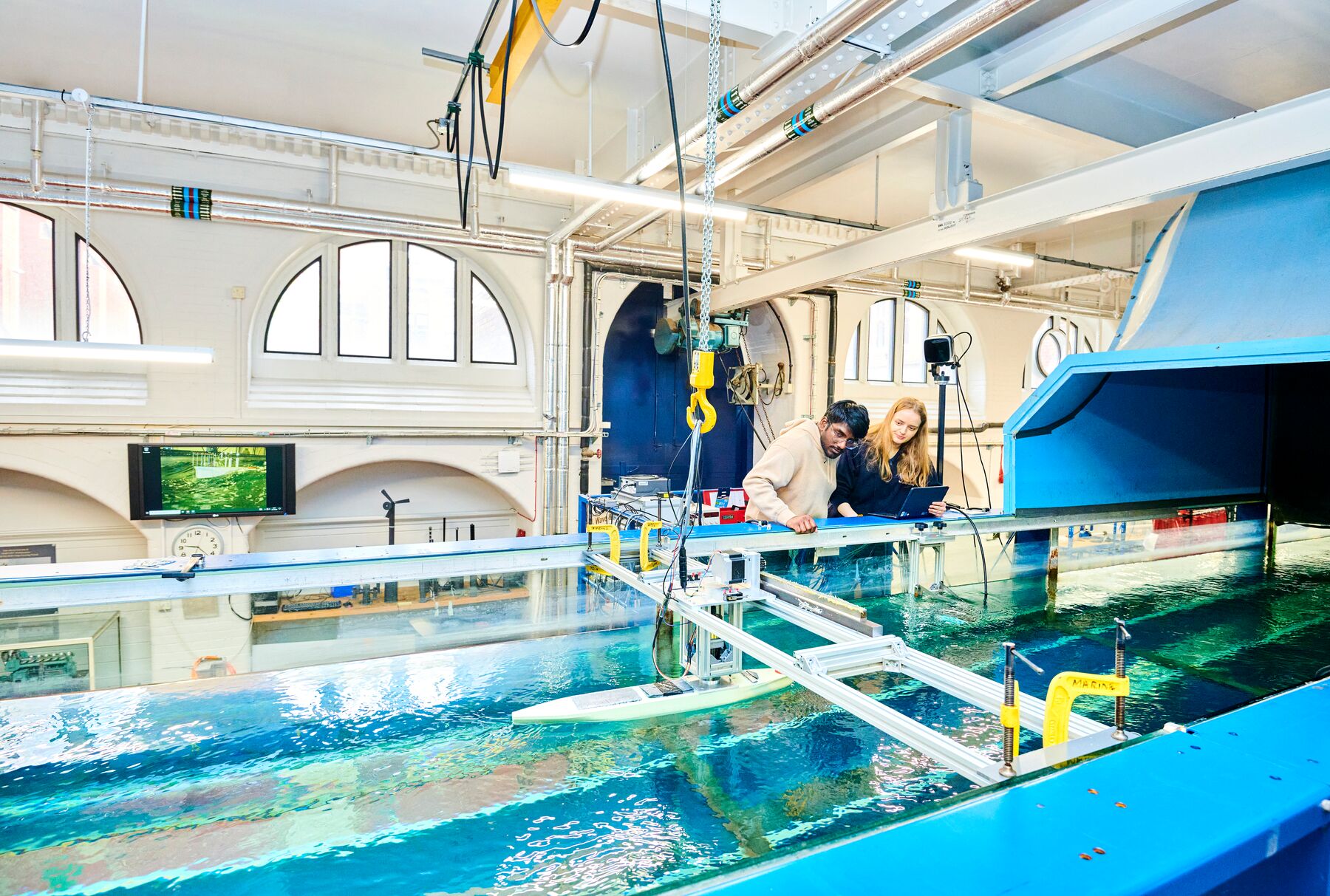

Towing tank

We use the Towing Tank mainly for calm water, wave resistance, and seakeeping experiments.

Since its construction in 1951 the Towing Tank at Newcastle has been in continuous use. It's regularly updated, including the fitting of wave-making and electronic recording equipment.

The wavemakers generate regular waves of up to 0.12m in height and wave periods in the range of 0.5-2 seconds. They're also capable of generating long-crested random seas using a variety of wave spectra.

A monorail carriage system that has a maximum speed of 3m/s in its normal mode tows models. The carriage can be remotely or manually controlled, while the 32-channel data retrieval system is online to a PC.

Find out more

Upgrades

Recent upgrades include the installation of a state-of-the-art motor control system to enhance very slow speed and high-speed testing capabilities as well as the latest wavemaker control software.

A recent innovation is a modern telemetry system which allows data sampling without any wired connections between the carriage and shore-based equipment.

Specifications

- Tank length: 37 m

- Width: 3.7 m

- Water depth: 1.25 m

- Normal Carriage velocity: 3 m/s

Wave capability

- Period range: 0.5 - 2 Sec

- Wave height: 0.02 - 0.12m (period dependent)

Wind, wave and current tank

The combined Wind, Wave, and Current Tank is one of only a handful of such facilities in the world. Its design allows for use with any, or all, of the components with equal emphasis.

The Wind, Wave, and Current Tank was designed with small scale model testing for renewable energy devices in mind. However, it is also suitable for standard resistance, seakeeping and wind loading experiments.

Find out more

Testing capabilities

The wind, wave, and current tank is capable of testing:

- wind loading on wet and dry structures

- resistance measurements

- seakeeping tests

- combined wind/wave/current interaction

- flow visualisation experiments

Specification

- Flume length: 11 m

- Width: 1.8 m

- Normal water depth: 1 m

- Air clearance: 1 m

- Central measurement section: 3 m

- Maximum water velocity: 1 m/s

- Maximum wind velocity: 20 m/s

Wave capability

- Spectra: Pierson-Moskowitz, JONSWAP, Bretschneider, Neumann

- Period range: 0.8 - 4sec

- Wave height: 0.02 - 0.12m (period dependent)

Flow Cell

The Flow Cell is designed to simulate the fully developed turbulent boundary layer developing over the hull of high-speed ships.

Constructed in 2005 as part of the AMBIO project, the Flow Cell investigates the use of nanotechnology in biofouling resistant coatings. A recent upgrade to the measuring section allows for usage of a range of test plates.

Instrumentation and equipment upgrades have kept the facility at the leading edge of research activity.

Microscope slides are covered with the trial coating and then different types of organisms are settled on them. The slides are introduced into the boundary layer and the wall shear stress is measured.

The Flow Cell also measures the adhesion strength of cyprid barnacles in a saltwater flow environment by simulating the boundary layers developing on a 140m vessel travelling at speeds up to 40 knots.

Find out more

Teaching

Each year students carry out experimental and practical projects in the laboratories. Teaching includes work relating to:

- marine diesel engine construction

- operation and performance assessment

- heat exchanger design

- exhaust gas emission measurement and analysis

The laboratory has a diesel engine test bed which has been adapted to operate using different fuels. This allows research into methods to improve engine efficiency, fuel consumption, and emissions.

Instrumentation

In addition to traditional instruments for engine tests, the Jones Laboratory has state-of-the-art portable engine emissions measurement equipment.

This equipment is capable of determining all kinds of species from the engine exhaust gases such as NO, NO2, HC, CO, SO2, CO2, O2.

Workshop capabilities

The laboratory is fully supported by marine, mechanical and electronic technicians. It has facilities for fabrication and machining to allow test rigs and prototype equipment creation in-house.

This provides the maximum flexibility and adapting test programmes to suit client needs.

Contact

For further information, contact Dr Weichao Shi at:

- Email: weichao.shi@newcastle.ac.uk

- Telephone: +44 (0) 191 208 6722

Marine Technology Special Collection

The Marine Technology Special Collection is now accessible for the first time.

It is a unique historical resource of marine technical documents from British shipbuilding. This includes marine engine building, ship repairing, and shipbreaking industries. The collection spans the mid-19th century to 2000, with an emphasis on the north east of England.

Newcastle University has made a significant contribution to this industrial heritage. Our work in offshore, subsea, and marine technology is globally renowned.

For over a century, we have played a leading role in the teaching and research of the marine technologies. This includes naval architecture, shipbuilding and marine engineering.

The University is well placed to help preserve and promote the north east of England. We recognise the region's vital contribution to the proud maritime heritage of Great Britain.

The collection owes its existence to a lifetime’s interest by University staff Ian Buxton and Brian Newman. Their dedicated collecting, storing, cataloguing, and fundraising has grown the collection.

The Collection is a member of the following UK national organisations:

- The Archives Hub, membership number Find An Archive (formerly ARCHON) GB3369 (Listed only with a brief description: no materials online)

- Discovery, National Archives

The Collection works closely with the University's Special Collections and Archives team, which is part of the Phillip Robinson Library.

Find out more

Historical resources

The Collection contains 318 linear metres of shelving (127m company documents, 191m technical publications) and the British Shipbuilding Database (BSD) of 80,000 UK-built merchant ships. Please download further details about our Historical Resources.

The Collection’s strength is that many of the company documents and some of the database’s ship information are unique. They are also supported by a wide range of associated technical publications in magazines, journals, textbooks, design rules, etc together with the subject expertise of our staff.

Opening hours and visiting

We welcome enquiries and visits from researchers and the general public, including individuals or groups for an informal tour and introduction to our range of resources.

The Collection can only accept visits made by appointment. To arrange an appointment e-mail marine.archive@ncl.ac.uk

Other times may be arranged, although we close on public holidays. All visits are by prior appointment only.

Please contact us to discuss your needs and/or to arrange your visit for a day and time that The Collection is open and to ensure that the materials you intend to consult are available. Identification is required.

Our expert staff offer a free advice service for simple, short enquiries only. Please download our example Enquiries Questions asked and questions searched for on the British Shipbuilding Database. Requests for more detailed research services will be considered case-by-case on a fee-paying basis.

Please download our Guidance for Visitors including handling, copying, photographing of materials, copyright, and our form Copying Declaration for Visitors.

Our team

Our staff are retired and have voluntary part-time appointments, including Doctor Ian Buxton a world-renowned expert on many aspects of shipbuilding and marine technology, and maritime history; compiler of the British Shipbuilding Database and the driving force for the establishment of The Collection. In June 2021 Ian received the prestigious award of an M.B.E. for services to the preservation of British maritime history. Other staff volunteers are Richard Carter, Prof. George Bruce, Richard Holme.

Donors and funding

Newcastle University’s Marine Technology Special Collection is possible thanks to generous support from Alumni and others. Please download Donors and Funding.

Volunteering

We welcome applications from people with a keen interest in marine technology historical research, together with industrial work experience, or appropriate qualifications to work with us as volunteers to assist with cataloguing and developing our Special Collection.

Contact and location

Our collection is housed in the Armstrong Building on Newcastle University’s central campus. Please see our campus and city map for directions.

The Marine Technology Special Collection

Newcastle University

Armstrong Building (Room 3.32)

Queen Victoria Road

Newcastle upon Tyne

NE1 7RU

United Kingdom

Email: armstrong.reception@newcastle.ac.uk or marine.archive@newcastle.ac.uk

Telephone: +44 (0) 191 208 6718 (Enquiries, School of Engineering, Armstrong Building) or +44 (0)191 208 3522 (MTSC)

Search our collection

The collection is partly catalogued but does not yet have an online catalogue. Please use the finding aids shown below. They are mostly a brief introduction to the subjects and holdings in the collection.

The collection holds two main types of documents: company documents and technical publications, which are listed in two catalogues:

- MTSC Catalogue 1 Archival Materials containing company documents. Most of our materials are now listed here. These contain unique documents including company records, brochures and catalogues, ships and works plans and also photos. These originate from, and are associated with, the industries of shipbuilding, marine engine building, shiprepairing, and shipbreaking (NB shipbreaking documents are listed on Catalogue No.3, to be added to this website shortly).

- MTSC Catalogue 2 Published Materials containing technical publications - magazines and journals, ship registers, directories, statistical & marketing reports, biographies, bibliographies, dictionaries, atlases & almanacs. All of our materials are now listed here including textbooks, popular/picture books, company histories.

- MTSC Catalogue 2 Published Materials Help

For further guidance see the company documents and technical publications listed below.

Collection Highlights

Short reports

A series of short reports are being written to highlight some of the unique materials in the Collection:

- Mauretania: a famous British passenger liner of 1907

- Titanic and Olympic: two of the most famous British passenger liners of ca. 1911

Emerson Cavitation Tunnel

The Emerson Cavitation Tunnel has its own scientific and technical staff, with comprehensive mechanical, electrical, electronic, and model-making technician support from within the School.

Many in the marine sector use it, including:

- ship owners

- shipyards

- propeller manufacturers

It also offers background research and development services for:

- cavitation

- noise

- propulsion

- turbines

- coatings

- hydrodynamics related activities

Download our Emerson Cavitation brochure here

Company documents

Many are unique, including:

Company records including correspondence, ledgers, minutes of meetings. Company publicity brochures and catalogues (not unique).

- Photographs: of company activities and their ships.

- Plans: layout plans of ships, yards, works, machinery, and equipment.

- Trials: ship and marine engine trial records.

- Letterheads of marine businesses are included in many of the above materials.

Most of these materials are from industrial companies of shipbuilding, shipbreaking (The Collection has the largest and most complete shipbreaking collection in the UK), ship repairing, and marine-engine building companies.

See also Companies, Company histories, Marine Engineering, Shipbreaking, Shipbuilding and Ship repairing.

Technical publications

The Collection divides technical publications and shelves them by type, including:

- Periodicals: lists the Collections holdings including trade and industry magazines & research journals e.g. The Motor Ship, e.g. Trans RINA. Histories of each title with example pages are in:

- Periodicals Histories A

- Periodicals Histories I

- Periodicals Histories M

- Periodicals Histories N

- Periodicals Histories S

- Periodicals Histories V

- Books: mainly historical textbooks.

- Company Histories: books about the detailed history of individual companies.

- Statistical & Market Reports: e.g. LR World Fleet Statistics. Examples given in Statistical & Market Reports Examples.

- Rules and Regulations: including national and international laws, design standards, etc. E.g. GB Department of Trade; IMO. See also Classification Societies, Government.

- Ship Registers: ship register books are official lists “directories” of the world’s ships. Examples given in Ship Registers Examples. See also Classification Societies, Trade Directories.

- Trade Directories: lists of companies and organisations with their facilities, services, products, staff, and addresses. Examples given in Trade Directories Examples. See also Ship Registers.

- Bibliographies: lists of references and indexes on specific subjects.

- Biographies: books about the lives of individual famous people. See also People.

- Dictionaries: including English and other languages, and translating dictionaries.

- Maps & Almanacs: Including maps, charts, & almanacs.

The Collection has other finding aids, including:

- British Shipbuilding Database: an authoritative and uniquely detailed database of 80,000 British-built ships of the 19th and 20th century. See also Ships.

- Classification Societies: including ‘ship register books’ for ABS, CCS, BV, DNV, GL, LRS / LR, NKK, RI. See also Rules & Regulations, Ship Registers.

- Companies: including shipbuilders, shipbreakers, ship repairers, marine engine-builders:- British Shipbuilders. Hughes Bolckow. Middle Docks & Engineering. North Eastern Marine. Shipbreaking Industries Faslane. Swan Hunter. T. W. Ward of Sheffield. William Allan Scotia Engine Works. See also Marine Engineering, Shipbreaking, Shipbuilding, Ship repairing.

- Government: mainly Great Britain, Board of Trade. IMO (International Maritime Organisation). See also Rules & Regulations.

- Learned Societies: professional trade associations for people such as naval architects. Including IMarE, NECIES, RINA

- NECIES Index to Publications 1884-1993 (PDF: 2MB)

- Shipbreaking

- Naval Architecture

- People: specific famous people including naval architects Bocler, H.; Telfer, E. V. See also Biographies.

- Shipbuilding

- Shipping and Maritime

- Shiprepairing

- Ships: specific famous ships including Great Eastern; Majestic, Mauretania; Olympic; Turbinia. See also British Shipbuilding Database.

Future plans

The Marine Technology Special Collection (MTSC). Preliminary sorting and cataloguing of the Collection is now complete after many years of work. As of 16th September 2024, ownership and materials are being transferred out of the University's Engineering School in the Armstrong Building to the University Library's Special Collections and Archives.

The MTSC's webpages will also be similarly transferred in the coming weeks to:

Marine Technology Special Collection - Newcastle University Special Collections and Archives

The University Library's Special Collections and Archives has an environmentally controlled storage facility, thus ensuring the future integrity of the MTSC and its materials. In due course, all the materials will all be listed on the University Library Catalogue and materials will be available for consultation. Until then please consult our MTSC catalogues listed above in Search Our Collection.

Virtual tour

Take a tour of the newly refurbished Cavitation Tunnel, relocated to its new home in Blyth.

Post from RICOH THETA. #theta360 - Spherical Image - RICOH THETA

Recent projects

We're always keen to engage new students in our exciting research work. Some of the more recent work we supported includes:

SeaFront

Synergistic Fouling Control Technologies. Sponsors: European Commission under the Seventh Framework Programme. Project website: seafront-project.eu

SONIC

Suppression Of underwater Noise Induced by Cavitation. Sponsors: European Commission under the Seventh Framework Programme. www.aquo.eu/SONIC.htm

TARGETS

Targeted and Advanced Research for Global Efficiency of Transportation Shipping. This project was STREP funded by the EU 7th Framework Programme (FP).

Research vessel replacement

An innovative replacement of Newcastle University’s research vessel, funded by Newcastle University and Newcastle School of Marine Science and Technology Alumni.

STREAMLINE

STrategic REsearch for innovAtive Marine propuLsIoN concEpts. This was a large-scale IP funded by the EU 7th Framework Programme (FP).

Port of London Authority (PLA)

We helped with the propeller design, performance, and cavitation testing for the new harbour patrol vessel 'Lambeth'.

AMBIO

Advanced Nano-structured surfaces for control of bio-fouling. IP funded by the EU 6th Framework Programme (FP).

Swirl-Jet

This project studied swirling jets in fields of seabed excavations, vessel propulsion and underwater cleaning. It was a CRAFT project funded by the EU 6th Framework Programme (FP).

Cavitation research

This project looked at the effect of cavitation on the performance of a podded propulsor during ice-milling. It was PhD research, sponsored by Sumitomo Heavy Industries Ltd.

FASTPOD

Fast ship applications for pod drives. It was STREP funded by the EU 5th Framework Programme (FP).

Tidal stream rotor performance research

An investigation of tidal stream rotor performance, which the EPSRC-RNET Programme funded.

OPTIPOD

This project looked at the optimum design and implementation of azimuthing pods for the safe and efficient propulsion of ships. It was STREP funded by the EU 5th Framework Programme (FP).

Marine surfaces research

This project researched the drag, boundary layer and roughness characteristics of marine surfaces with anti-fouling coatings. It was PhD research, jointly funded by International Paint Ltd and EPSRC.

FLOWMART

Fast low wash maritime transportation. STREP funded by the EU 5th Framework Programme (FP).

Dynamometer Specifications

Type 1 - Kempf & Remmers H33 propeller dynamometer

|

Max thrust |

± 2943 N |

|

Max torque |

± 147 Nm |

|

Max rpm |

4000 rpm |

Type 2 - Kempf & Remmers R45 with vertical adjustable drive system

Suitable for placement inside of hull models.

|

Max thrust |

± 687 N |

|

Max torque |

39 Nm |

|

Max rpm |

4000 rpm |

Propellor testing

The Tunnel allows us to conduct conventional and unconventional propeller performance tests, including shaft inclination in three axes.

This facility can host boundary layer and drag tests with flat planes, submersible bodies, and propellers with coating.

Propeller testing in simulated ice blocks.