Research Theme: MEMS and microsystems

Our research focus is on:

- MEMS (microelectromechanical systems)

- nanotechnology

- smart materials

- micro-manufacturing

We collaborate in multi-disciplinary research teams based at Newcastle University. We have access to the University’s own fabrication facilities as well as extensive laboratories.

Our work is divided into four areas.

Modelling and design

We use:

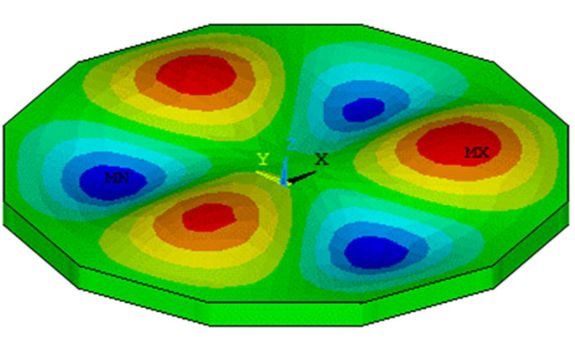

- analytical models to optimise design parameters to meet performance specifications

- finite element models to support the analytical calculations

A key part of the modelling and design process is determining suitable materials and processing parameters.

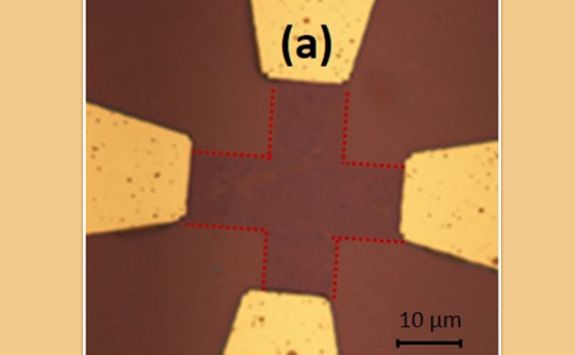

We design a wide variety of sensors, including:

- biosensors for the detection of infectious diseases

- gyroscopes for inertial measurement applications

Micro-manufacturing

We develop both MEMS and non-MEMS based micro-manufacturing approaches within the group. We devise processes for a wide range of engineering materials.

We use the University clean room facilities for traditional microfabrication approaches.

We develop rapid prototyping methods. These allow for faster turnaround times during the prototyping phase. Approaches include high speed micro milling, laser fabrication and printing methods.

Characterisation

We use XPS (X-ray Photoelectron Spectroscopy). This is one of the principal methods of probing the composition and electronic structure of surfaces.

TOFSIMS (Time-of-Flight Secondary Ion Mass Spectrometry) gives accurate compositional information at high spatial resolutions.

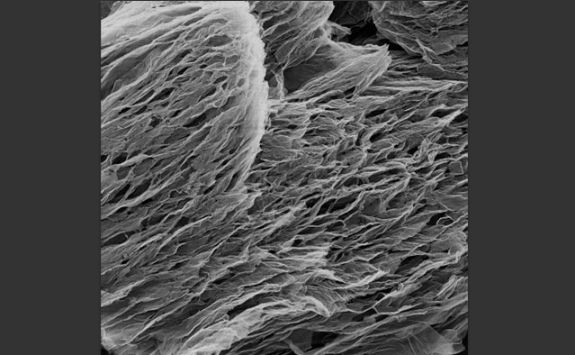

We also use SEM (Scanning Electron Microscopy) and He-ion microscopy. These give unprecedented imaging resolution for the nanostructure of our sensors and micro-machined surfaces.

Laser vibrometry characterises the motion of resonant based sensors down to atomic precision.

We use VNAs (Vector Network Analysers) and lock-in amplifiers to characterise electrical performance.

Implementation

We work with colleagues in the Faculty of Medical Sciences. Together, we have functionalised sensors targeted towards biological analytes. We have benchmarked according to clinically relevant analyte concentrations.

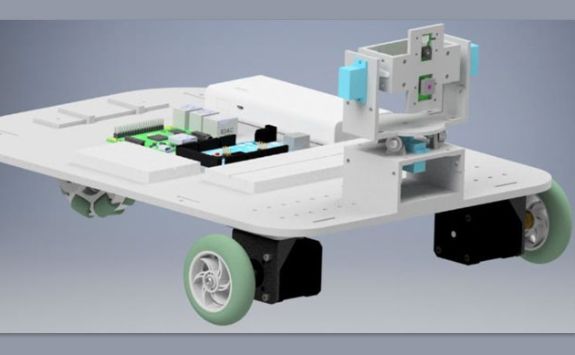

We trial environmental sensors as static systems and on autonomous robots developed within the group.

We develop hybrid micro-manufacturing methods, including:

- hybridisation of material deposition and micro milling

- vibration assisted micro machining

We work closely with our industrial partners. Together, we implement developments in the control and performance of physical sensors.