Innovative machine topologies for use in More Electric Aircraft (MEA)

We are working with industrial and academic partners to develop the next generation of MEA components.

Project leader

Dates

May 2014 to April 2017

Sponsors

Partners

Safran Power UK Ltd, Arnold Magnetics and Teesside University

Description

We are targeting many auxiliary components for both fixed wing and rotary civil aircraft, including:

- flight control surface actuation

- hybrid propulsion

- high pressure pumping

- landing gear and wheel applications

- power transfer

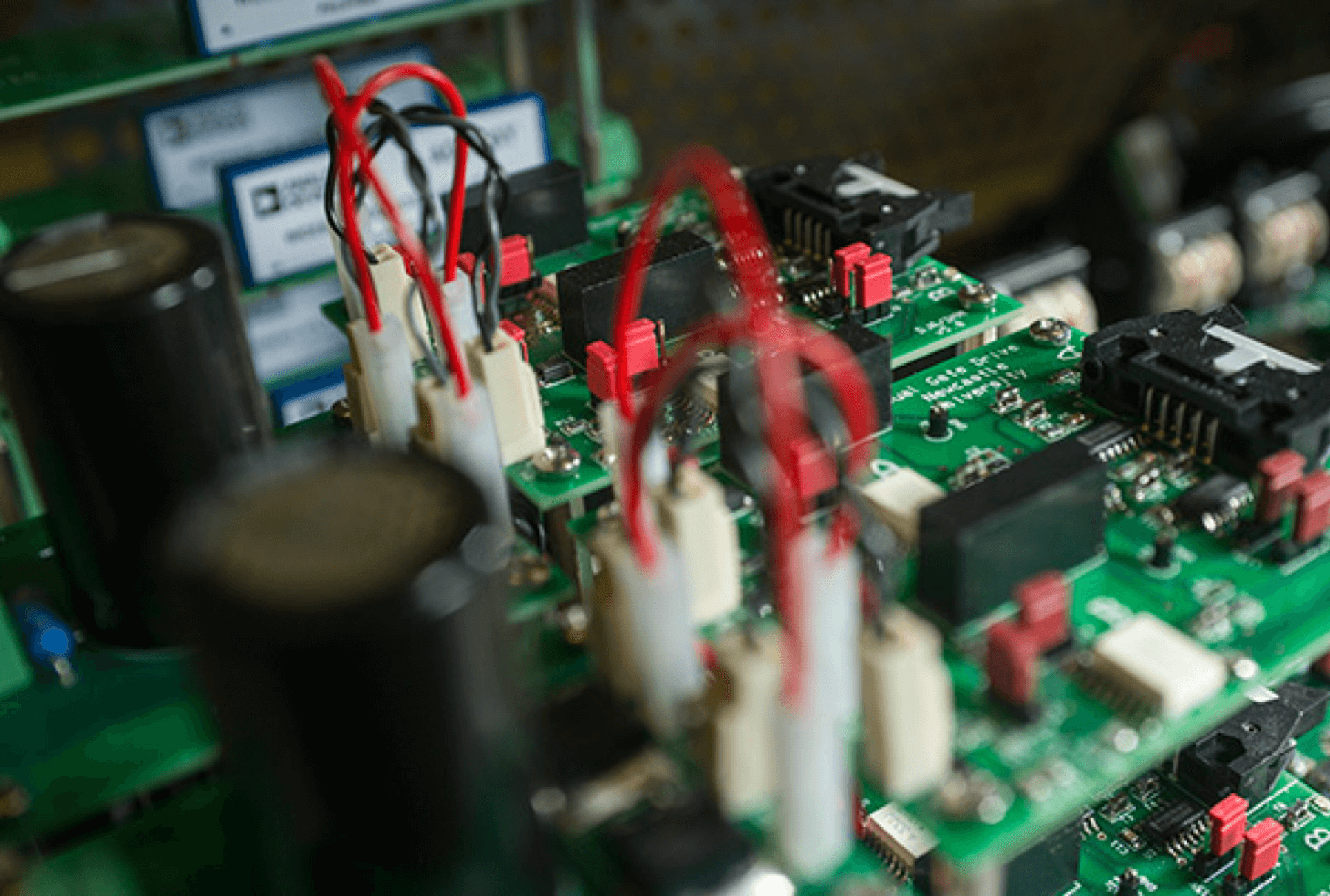

The consortium will produce the mechanical and motor elements of high added-value drive systems. Newcastle will develop and demonstrate new machines in a laboratory environment. We will prove that they can replace existing hydraulic actuators.

We will show that each topology has:

- fault tolerance compliance

- adequate power density and class leading efficiencies

We will exploit the opportunities provided by new materials. Our designs will have the potential for low cost industrialisation and manufacture.

We will ensure design optimisation. To do this, we will use leading edge software and cross-fertilisation from outside of the aerospace sector.

The consortium’s aims

Together, the project partners will produce prototype machines for aerospace actuators. The machines will have adequate redundancy and resilience to short circuit operation.

The consortium will develop machines fabricated with high density bobbin windings. We will develop machines in a realistic manufacturing environment. We will investigate the development of high speed motors for this application.

We will exploit laminated magnets to demonstrate low loss topologies. We will also demonstrate high torque density actuators incorporating high temperature conductor materials.

We will apply optimisation techniques to designs selected for manufacture and reliable assembly.

We will explore the use of reduced or zero rare earth machines for safety critical and non safety critical high torque density roles.

We will investigate the integrated design of electric drive and load components. These include, for example, motor/gearbox and motor/component.