Increasing the lifespan of Powered Air Purifying Respirators (PAPR)

Developing an adaptive controller and a modular system for PAPRs.

Project leader

Dr Steve McDonald

Dates

January 2016 to March 2020

Project staff

Prof Barrie Mecrow, Dr Simon Lambert

Sponsors

Partners

Defence Science and Technology Laboratory DSTL (Porton Down)

Description

Standard gas masks work by negative pressure. The user must inhale through the filter to clean the air. The filter can be very thick, creating a large resistance to breathing. This causes discomfort and can impair physical performance.

Powered air purifying respirators provide protection against contaminated air. They contain a filter, centrifugal blower and a motor powered by a battery. The centrifugal blower in PAPRs provides positive pressure. It minimises the resistance caused by the filter by drawing air through it.

Until recently, PAPRs have provided a constant flow of air. But protection is reduced when breathing increases due to increased physical exertion. Also, filters have a lifespan dependent on the concentration of the gas they filter and the volume of airflow. The centrifugal blower only providing air on inhalation would increase the lifespan of the filter.

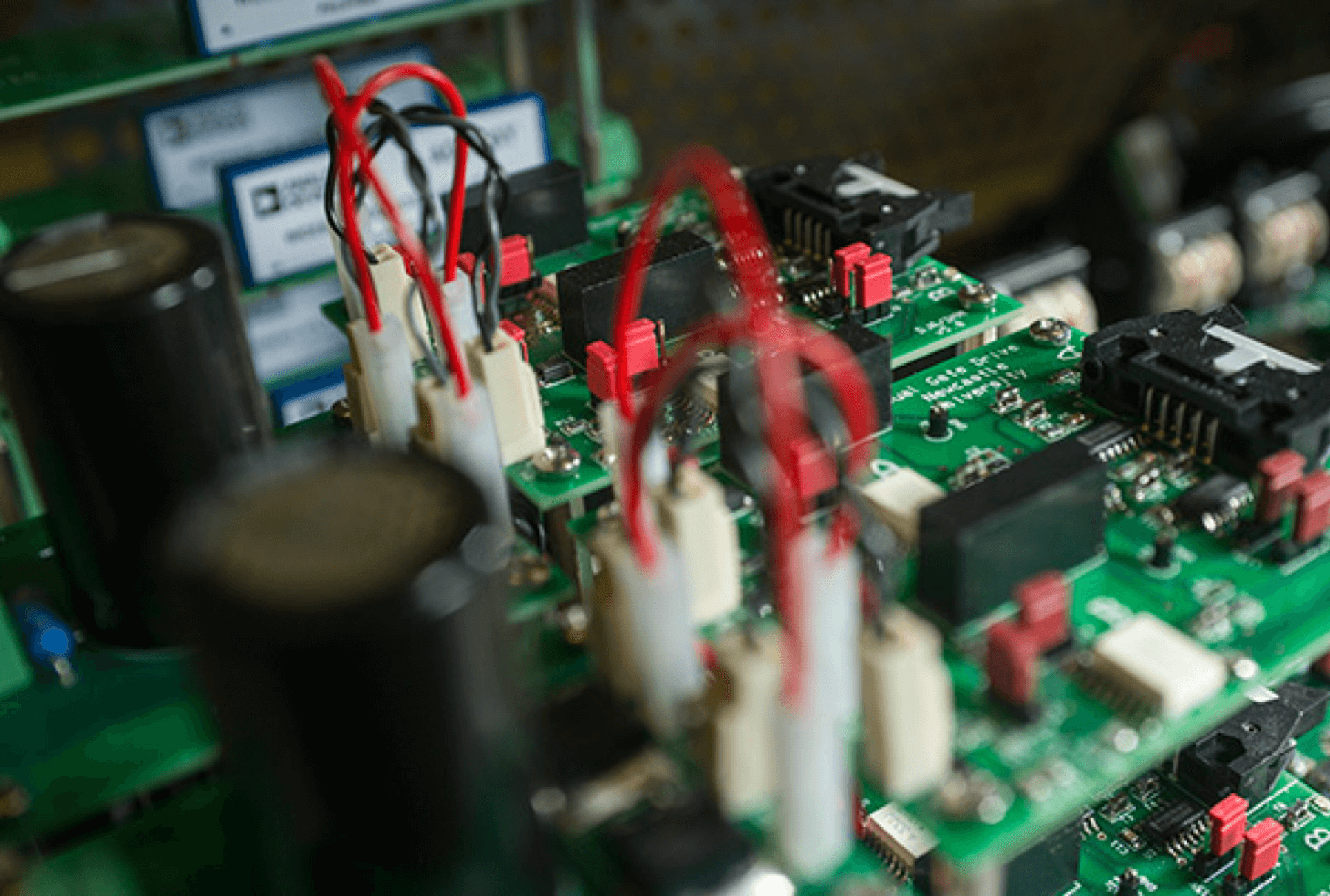

Small changes to individual components can create large changes in performance. So creating a controller for an individual case is difficult, as developments to optimise components would make it subpar. We will develop a controller that will account for individual developments in the PAPR components. In other words, we will make the design of the system modular. Thus, the controller would also be able to change depending on changes to the system. Such changes could include the thickness of the filter, the shape of the mask, the centrifugal blower, and the motor.