Underpinning Power Electronics - Integrated Drives

Project leader

Dates

July 2013 to June 2017

Sponsors

Description

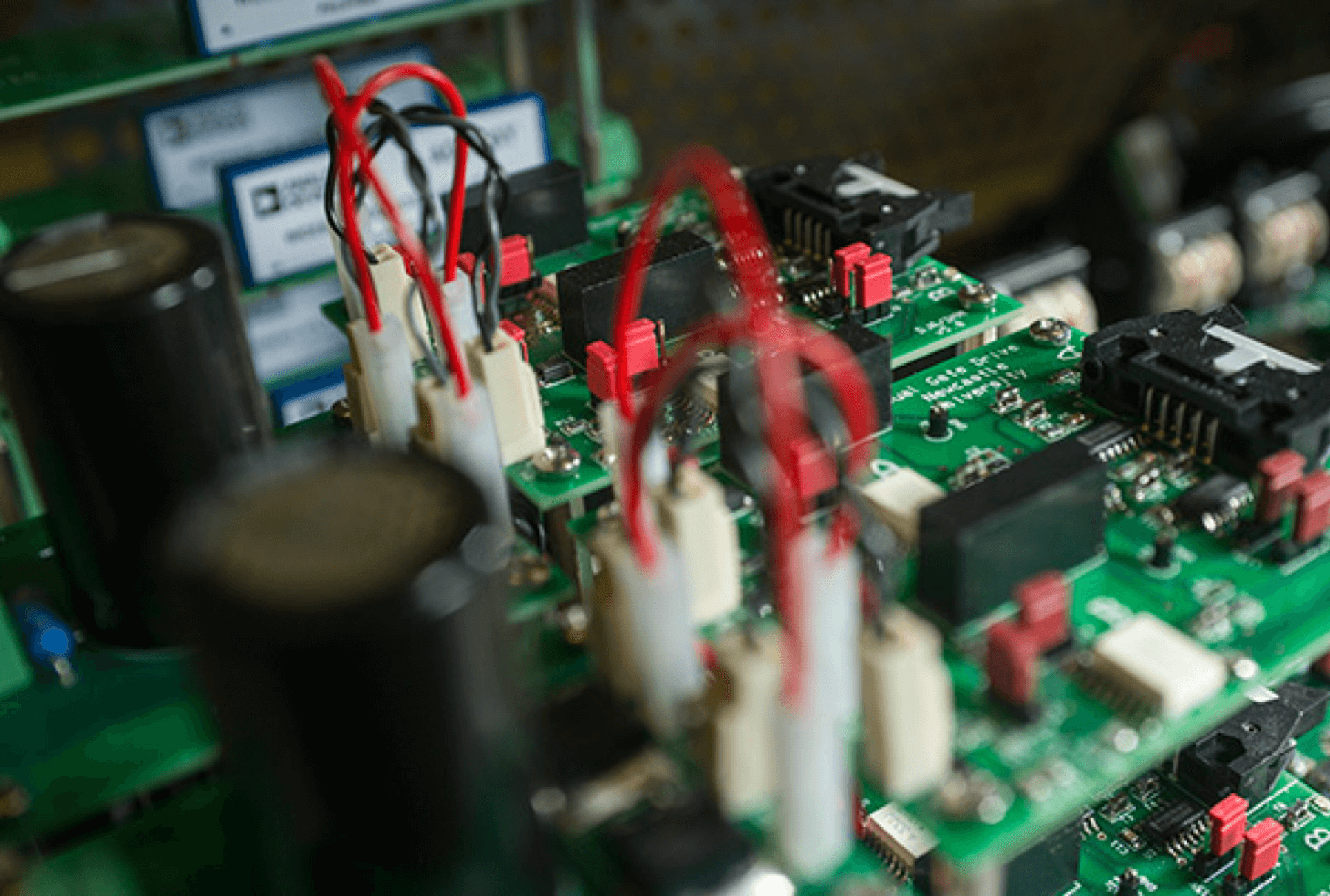

Newcastle University is leading a new programme to undertake novel research in electric drives. in collaboration with the Manchester, Nottingham, Sheffield and Bristol universities. This forms part of the Underpinning Power Electronics Initiative which has four themes: Devices, Components, Converters and Drives. Together, this has formed a Virtual Centre for Excellence in Power Electronics based at Nottingham.

An electric drive is a system which includes a power electronic converter, an electrical machine and a controller. It is a key enabling technology which is penetrating into almost all sectors of industry. It provides exciting opportunities in most sectors, particularly aerospace, automotive, renewable energy generation, industrial processes, and consumer products.

Electric drives:

- contribute to cost effective and efficient renewable energy generation

- enable adoption of "more electric aircraft" technology

- provide traction power for electric propulsion in railways, ships and cars.

The world market for industrial drives is over £8.5 billion. This has grown between 2% and 5% above the industrial average over the past 30 years. This increase is due to the growth of industrial automation for better quality, productivity and management. The technology also delivers energy saving for cost reduction opportunities. These are increasingly supported by regulations such as the climate change levy (UK Department for Business Innovation and Skill report: Power Electronics Strategy for Success).

Advances in electric drives are crucial for the UK's economic growth and competitiveness. They can make a huge contribution to the low carbon economy. They can help to achieve the UK Government target of 15% of all energy generation to come from renewable sources by 2020.

Although electric drive technology is established, many challenges lie ahead. These include:

- adding new functionality

- improving efficiency and compactness in drives as well as the overall system

- better availability and condition monitoring

- increasing power density

- the ability to operate in adverse environments

Underlying all this is the drive for lower costs. The technology is advancing rapidly. But we must embrace new developments in components and emerging markets quickly to maintain a competitive advantage. We must also address the constraints on material supply chains, such as rare earth magnets.

This theme will encompass a wide range of research, including:

- the physical integration of the drive

- design of components

- integrated design of the system, using a holistic approach

We will advance a selection of challenges:

- Increased Efficiency

- Increased Power Density

- Greater Functionality

- Increased Robustness

- Higher Levels of Integration

- Lower Electromagnetic Interference (EMI)

- Lower Life Cycle Costs

Many of these will embrace transformational research topics as opposed to incremental advances. Lower costs will be a key over-arching feature of the theme. Although some manufacturing costs are independent of this programme, we will reduce component and life-cycle costs. We will work closely with industrial partners to ensure manufacturing costs are not ignored.

A systems approach in this theme is essential. We will develop devices and converter concepts under other themes. With the exception of the machine and controller, this aspect is about integration. We will develop modelling tools to enable system optimisation. This will enable us to understand motor, converter and load trade-offs. In turn, this will allow us to design for greatest efficiency, life cycle costs or power density. Finally, this progresses into the topic of design for manufacture.